Anything but Standard

Standard roofing shingles are just that – standard. But they don’t have to be. You can make a shingle that performs better, protects longer, and is more sustainable. We know, because we do.

Here’s how…

NEX® Polymer Modified (Rubberized) Asphalt

We rubberize the asphalt core of the shingle so that it performs more like vulcanized rubber than hard asphalt.

This process, which we invented, makes the shingle stronger, more durable, and more resistant to stress, breaking, cracking, granule loss, and hail damage.

Polymer Modified (Rubberized) Adhesive

We rubberize the adhesive used throughout the shingle too (laminate seals, wind seals, rain seals).

This process creates a stronger adhesive bond, that better resists dry-out, for extreme protection from shingle delamination, high winds, and leaks from wind-driven rain.

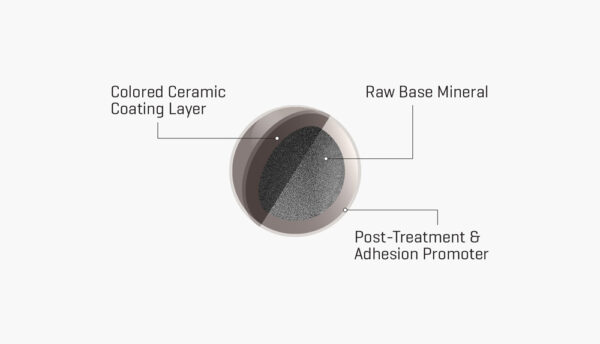

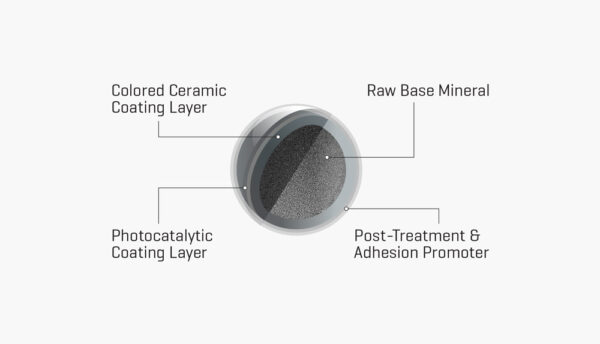

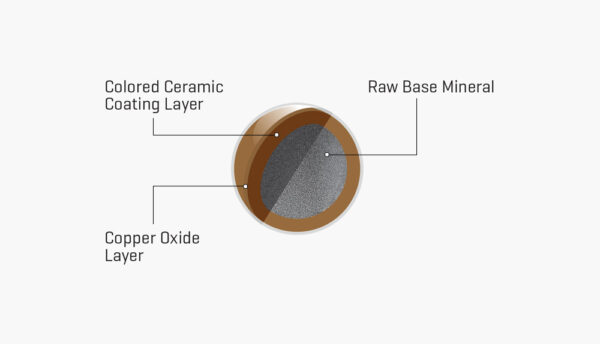

3M™ Roofing & Specialty Granules

Granules are important. They add color and impact resistance to the shingle. They also serve as sunscreen, protecting the shingle from one of its biggest threats – UV aging. For granules, we’ve turned to the expertise of 3M for over 50 years.

The Zone® Larger Nailing Area

We invented the larger nailing area. It takes over 7,000 nails to install a roof. Even one out of place can lead to leaks, shingle uplift, or blow-off.

A bigger nailing area improves installation speed & accuracy, and makes room for an extra rain seal – double that of standard shingles.

Sustainable Design

Malarkey shingles are made to last, of a cleaner technology, incorporating recycled tires and plastics, integrating smog-reducing granules, and accommodate solar panels.

Shingles made cleaner, greener, and to last longer.

*The algae protection warranty applies only to blue-green algae (Gloeocapsa magma). The warranty does not extend to, and expressly excludes, all other forms of algae, mold, mildew, lichens, moss, or any other biological growths. Coverage is subject to the specific terms, conditions, and limitations set forth in the applicable warranty documentation.