Roofing Contractor Safety is Key at the Season’s Start

The warmer summer months are a popular time for homeowners to consider roofing projects. Roofing contractor safety should be a top priority before crews get busy.To ensure the season is not just busy, but long and successful for professional roofing contractors, they should begin with a focus on safety. From driving to the job site, to cleaning up after completion, there are many ways to work safety into any project. Here are few key areas for roofing contractors to remember.

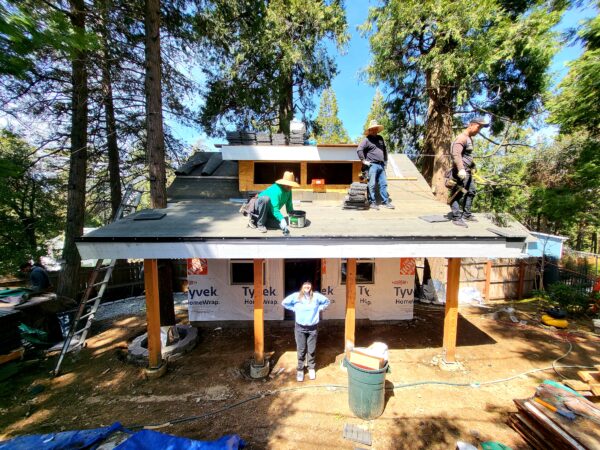

Stay Safe Up Above

Roofing, unlike many other trades, requires crews to work from significant heights. For certified roofing professionals, exercising proper safety precautions while working on a roof is critical. Even small roofing repairs require the hauling of heavy tools and equipment up and down a ladder – often tens of feet high. To do so, roofing crews must be especially trained in tool handling and fall safety techniques; in fact, this is one of the main reasons homeowners are advised to avoid roofing their own homes. Contractors, be sure your crews receive preventative safety training, including the proper use of specialized, lifesaving, fall safety equipment.

Aside from fall hazards, roofing tools such as pneumatic nailing guns, and roofing-specific hatchets and knives have their own required cautions for safe use. For instance, in addition to fall safety equipment, many professionals wear protective gear such as glasses, hard hats, and ear plugs, to prevent residential roofing accidents. Ample training and experience not only help professional roofing contractors get the job done quickly, but safely.

Each year, the Occupational Safety and Health Administration (OSHA) sponsors the National Safety Stand-Down to Prevent Falls in Construction. A Safety Stand-Down is a voluntary event for employers and employees to have a direct discussion about general safety, fall hazards, and fall prevention. Participating organizations have included commercial construction, residential construction contractors, sub- and independent contractors, unions, the U.S. Military, and more. At the beginning of a busy roofing season, this event is a great way for crews to refresh their skill set.

Plan to Handle Heat

In addition to spending the day at significant elevations, roofing crews are also exposed to serious temperature increases in the summer months. For reference, roofing shingle product tests have found that even on mild, 70°F days, roof temperatures can quickly exceed 120°F by midday.

Exposure to extreme heat can result in occupational illnesses and injuries,” according to the Centers for Disease Control. “Heat stress can result in heat stroke, heat exhaustion, heat cramps, or heat rashes. Heat can also increase the risk of injuries in workers as it may result in sweaty palms, fogged-up safety glasses, and dizziness.

To work safely in high temperatures, professional roofing contractors need to have a plan in place, one that includes best practices for avoiding and mitigating exposure to extreme heat. Roofing crews may for instance, plan to start early and clean up before the day’s temperatures peak. They may also take several breaks per hour to drink water and maintain hydration while working in heat. OSHA and the National Institute for Occupational Safety and Health (NIOSH) have even created a phone app to help crews with tips for handling heat stress.

Avoid Asbestos Exposure

Replacing roofs on old homes, as with other renovation or remodeling projects, may hold a risk of asbestos exposure. Prior to the 1970s, many types of building insulation products were manufactured with asbestos for heat and fire resistance. Asbestos has also been widely publicized as a cause of mesothelioma cancer and other pulmonary diseases.

“Families of roofers,” according to the Mesothelioma.com, “were also placed at risk because their loved ones would bring asbestos fibers home on their clothes and shoes from the job. They were then placed at risk of inhaling them.”

This condition can take 30 or 40 years to manifest itself before showing physical symptoms, so it is often too late to effectively treat the disease once it is diagnosed. Professional roofing contractors should check to be sure there is no risk to asbestos exposure before opening a roof deck.

Malarkey Roofing Certified Residential Contractor Program

Safety is the top priority at any job site, and especially so for roofing. Homeowners are also encouraged to understand this aspect of the roofing process – not only to avoid the unnecessary risks in doing their own roof repairs, but to recognize qualified crews from inexperienced novices. There are many resources available to roofing crews for education and training, such as the Malarkey Certified Residential Contractor (CRC) Program.

The mission of the CRC Program is to bring together established, industry roofing applications with factory trained applicators that use high-quality Malarkey roofing products. Malarkey CRCs deliver roofing excellence to homeowners with professionalism, safety, and an installation that ensures the best use of our roofing products. This certification program requires a step-by-step application process to ensure contractors are current on the latest industry accepted application procedures and installation techniques. Contractors can also earn recognition with badges based on specific criteria, training, and overall professional experience.

Homeowners can always trust CRCs will consider safety job one when installing your Malarkey roof.